We offer PCB assembly customized services,Why can we excellently complete customer’s needs ?

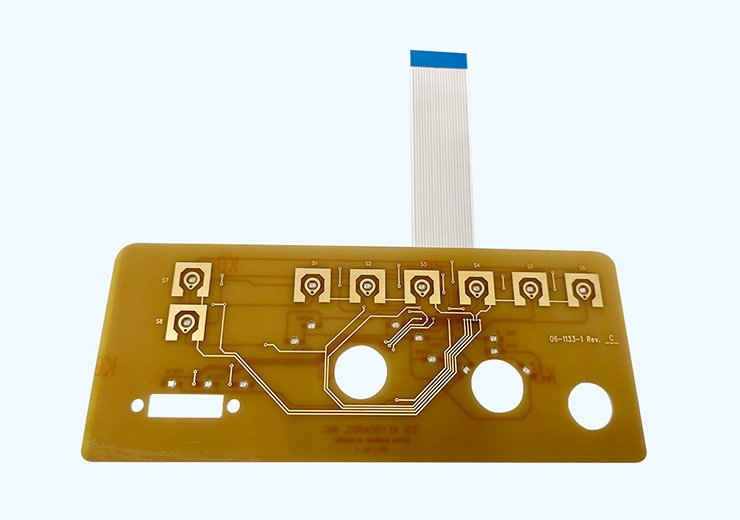

Feature products

Layers: 2 – 8 layers

Material: DuPont PI, Domestic Shengyi PI

Board Thickness: 0.1mm – 0.8mm

Board Size: Min 6*6mm, Max 406*610mm

Copper Weight: 4mil

PCB Outline: 0.5oz – 2.0oz

Min Line: 3mil

Layers: 1 – 48 layers

Material: RO4003C,RO4350B,Ro3003,RT5880

Board Thickness: 0.4mm – 5.0mm

Board Size: Min 6*6mm, Max 700*460mm

Copper Weight: 0.5oz – 4.0oz

Min Line: 3mil; Min Space: 3mil

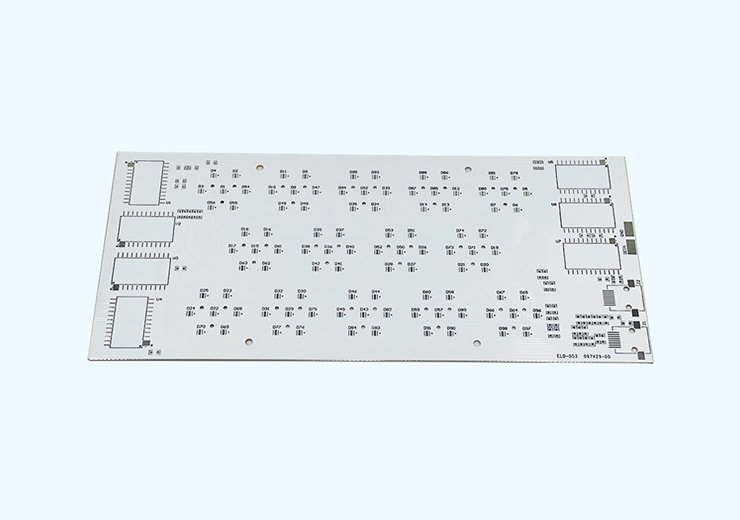

Layers: 1 – 2 layers

Material: Aluminum

Board Thickness: 0.4mm – 5.0mm

Board Size: Min 6*6mm, Max 800*2000mm

Copper Weight: 0.2oz – 4.0oz

PCB color: White, Black, Green,Blue ,Red

Min Line: 3mil

Layers: 1 – 48 layers

Material: FR4, Aluminum, FPC, Ceramics

Board Thickness: 0.1mm – 4.0mm

Board Size: Min 6*6mm, Max 700*460mm

Copper Weight: 0.5oz – 4.0oz

PCB Outline: Square,circle,irregular

PCB Color: White, Black, Yellow,Green ,Blue,Red

Min Line: 3mil; Min Space: 3mil

Layers: 2 – 24 layers

Material: DuPont (PI25UM), FR4

Board Thickness: Min 6*6mm, Max 457*610mm

Board Size: 8mil

Copper Weight: 0.6mm – 5.0mm

PCB Outline: 0.5oz – 2.0oz

Min Line: 3mil; Min Space: 3mil

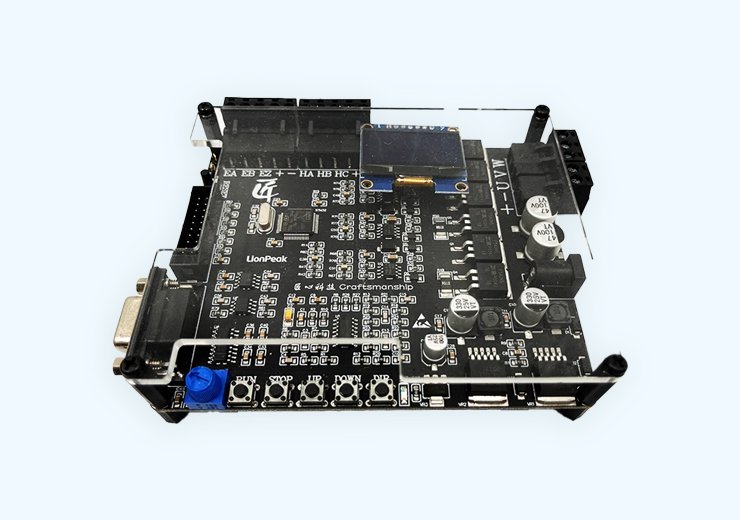

0201 SMD chips, 0.4mm pitch BGA, QFN, POP, bonding, inspection by SPI, AOI, X-Ray and other instruments, 100% function test of board before shipment

Customized services

You only need to send us the PCB Gerbers, BOM and special process requirements to enjoy the following high-quality PCBA electronic manufacturing services

1.The production process of PCB assembly sample (including PCB, components sourcing, SMT, DIP & test) within 3 days

2. The project cost is at least 30% lower than the market price.

3. Free of charges for DFM inspect,ensure 100% passed before shipment.

4. Perfect package :Electrostatic bag + bubble bag + carton safety packaging

5.MOQ :1PCS

1. We will strictly implement the small sample production process drawing for trial production.

2. Carry out welding, testing, problem analysis, test report summary, and corrective measures in accordance with the mass production process.

3. Conduct secondary verification on the modified small sample process drawing.

4. After all problems are eliminated, seal the sample. R&D preservation samples.

5. Officially issue the correct process drawings for mass production.

Dragon production scene

We provide turnkey solution including PCB fabrication, SMT, plastic injection & metal,final assembly, testing and other value-added service.

For PCB: Quantity, Gerber file and technical requirements(material,size, surface finish treatment, copper thickness,board thickness).

Our MOQ is 1 PCS, sample and mass production all can support.

China dragons’ QC departments inspect every tiny details of SMT and components of through-hole,ensures all of them work well before shipment .

es , every assemblies are complied with RohS (The European Union’s Restriction of Hazardous Substances Directive .)

What can we do for you ?

Our main business including PCB fabrication, PCB assembly, PCB design, NPI, burning software, injection molding, box build, function testing, color box Packing and shipment etc. Dragon PCB has a solid quality management system (QMS) and includes ISO9001, ISO13485, IATF16949, UL, and RoHS certifications to ensure that your circuit boards have a higher level and stable performance in the market. What you can do is trusting us , hands over all complex processes to us .